corrosion protection : Steelpaint

SP-PUR-ZINCING System (PDF Brochure)

SP-PUR-ZINCING System (PDF brochure)

The brochure by Steelpaint introduces the SP-PUR-ZINCING system as a highly reliable solution for long-term cathodic corrosion protection in shipbuilding and port construction. It is specifically designed for high-stress steel areas such as cargo holds, tanktops, deck areas, and hatch covers, where cheap standard coatings typically fail after brief exposure.

Steelpaint emphasizes that practical, real-world performance is what counts – not just lab tests or certificates. Numerous reference projects, including vessels from Oldendorff and Berge Bulk, as well as infrastructure like the Columbus Quay in Bremerhaven, demonstrate exceptional corrosion resistance even after 9+ years, often without requiring recoating.

SP-PUR coatings maintain performance even when surface preparation is limited to high-pressure water jetting, proving robust under mechanical stress, saltwater, and UV radiation. Unlike cheap mass-market alternatives, SP-PUR systems do not become brittle or flake, avoiding costly repairs.

The core message is clear: Those who buy cheap pay twice. While SP-PUR-ZINCING may be more expensive upfront, it significantly reduces maintenance, repair cycles, and long-term costs, offering peace of mind and sustainable value.

Bottom line: Once used, SP-PUR-ZINCING proves its quality — and is used again and again by those who prioritize durability and reliability in tough environments.

Ultimate corrosion protection for Ships (PDF)

Ultimate corrosion protection for Ships (PDF)

Ultimate corrosion protection for Ships (PDF)

Overview of Steelpaint's corrosion protection solutions for the shipping industry. The benefits of advanced polyurethane coatings, offering durable protection for vessels and structures, ensuring long-term performance in harsh marine conditions.

Interactive brochure:

Als interaktive Broschüre öffnen (Externe Website)

Download brochure as PDF

Ultimate corrosion protection for Ships ![]() 6.01 MB

6.01 MB ![]() 1,818 Download

1,818 Download

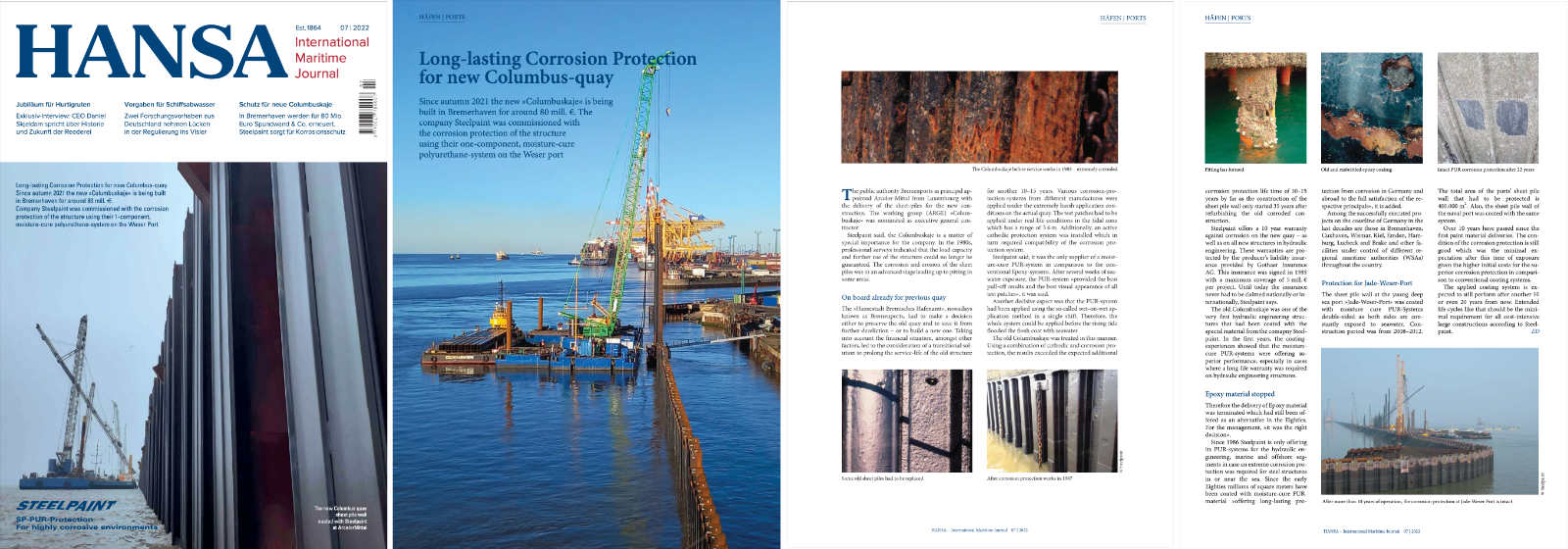

Long-lasting Corrosion Protection for new Columbus-quay Steelpaint

Long-lasting Corrosion Protection for new Columbus-quay

Since autumn 2021 the new »Columbuskaje« is being built in Bremerhaven for around 80 mill. €.

Company Steelpaint was commissioned with the corrosion protection of the structure using their 1-component, moisture-cure polyurethane-system on the Weser Port.

Read the full article as PDF:

Source: HANSA 07-2022 - International Maritime Journal

Mit freundlicher genehmigung von:

Schiffahrts-Verlag “Hansa” GmbH & Co. KG

https://binnenschifffahrt-online.de/

Ein Unternehmen der Tamm Media

Stadthausbrücke 4 · 20355 Hamburg

Tel. 040/70 70 80-225

The ultimate protection against corrosion

For more than two decades, Steelpaint has decisively enhanced the life and durability of heavy-industry facilities, particularly in maritime service. Thanks to one-component polyurethane resins, our special high-tech Steelpaint coatings have raised the technological bar in corrosion resistance, offering impressive benefits over conventional epoxy coatings.

SP-MCPU - allround protection

Year after year, millions are lost as facilities succumb to corrosion. Long-term protection of valuable investments calls for long-term protection of facility surfaces. Thanks to its unparalleled long-lasting performance, SP-MCPU is increasingly the coating of choice, winning out over conventional epoxy-resin systems. When it comes to battling aggressive industrial gases, mechanical stress, abrasion, salt water and the elements, SP-MCPU solutions offer standout performance in a wide array of application settings:

- Piers, sheet pilings, moorings, bridges, jetties, cranes

- Ships, offshore platforms, barrages, locks, ship hoists

- Pipelines, tanks

- Industrial facilities, power plants, refineries